Orientation: The spindle inside of a horizontal lathe is positioned horizontally, with the workpiece mounted perpendicularly to the axis.

G-code data files: stands for geometry code, and features the machine’s motion coordinates so which the machine is aware of wherever to chop chips off the portion, which sort of CNC machining tool to implement, how quickly to maneuver the spindle, the radius of arcs specified from the machine, and also the speed settings.

These early versions laid the groundwork for that CNC lathes that became integral in fashionable manufacturing.

Every one of these machines are actually terrific in their own individual capacities and should be able to tackle almost regardless of what you may throw at them.

Then together came the primary pcs. These early desktops, even though primitive, could generate their own punched tape according to specific inputs. This drastically increased the speed at which commands may very well be made.

So mainly what it will come down to is choice. When you or your machinists are more relaxed with a Haas or maybe a Tormach then it could seem sensible to stay with what you understand.

In some cases called die sinking or spark machining and also spark eroding, EDM machining will involve electrical discharges from sparks to chop and form parts.

The cookie is about with the GDPR Cookie Consent plugin and it is accustomed to store whether or not person has consented to the usage of cookies. It does not store any particular information.

You'll be able to see their wonderful rookie CNC mill right here, but for now, we wish to attract consideration to the 4029 CNC lathe. Comprised of the 5C headstock, ball screws, in addition to a DSLS shut-loop control system, this machine emphasizes the delivery of accurate outcomes.

In machine constructing, you cannot bypass shafts to transmit energy within the motor to your shifting parts. Shafts, obviously, involve turning. But CNC turning and unexciting find loads of use in different industries to provide typically axi-symmetric parts.

Having said that, these expenses could be offset when developing a lot more important portions. Operating Get started with knowledgeable partners like MakerVerse will help speed up setup situations and lower costs.

In contrast, CNC milling includes a workpiece secured to some movable table. In such a case, the reducing tool rotates and moves in the steel piece, getting rid of product and creating a flat surface.

Ongoing checking of your machining procedure to be certain accuracy and detect any deviations or issues that could come up.

3D Modeling Software: Employed for producing complex 3D models that may be translated into machining functions. Rhino and Blender are suited to more creative or intricate styles.

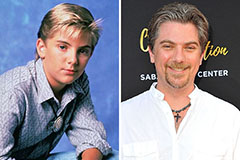

Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Jenna Jameson Then & Now!

Jenna Jameson Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Heather Locklear Then & Now!

Heather Locklear Then & Now!